Meet Your Team, Part I: Our Engineers

Engineered for Excellence

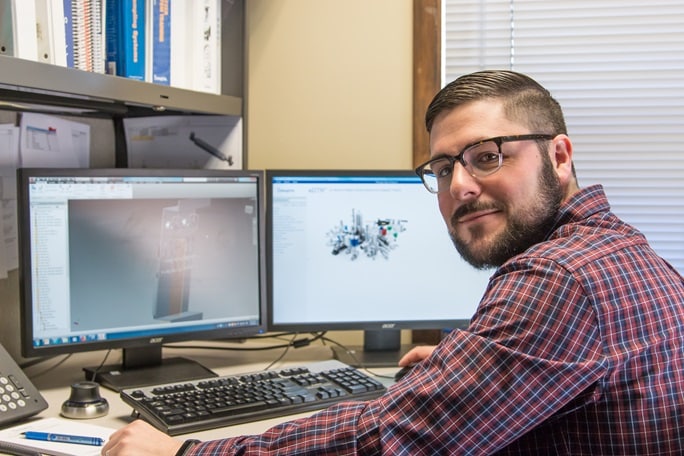

Gary Osman, Application Engineer at Swagelok Pittsburgh | Tri-State Area

When customers engage with Swagelok Pittsburgh | Tri-State Area for fluid-system assistance, they’re looking for trusted problem-solving expertise. And, for almost 55 years, we’ve proven that, on routine applications to the most intricate field challenges, our customers have been coming to precisely the right place.

Our proven technical experts, like Application Engineer Gary Osman, are the primary reason why. He is one of five resident certified engineers who ably address customer fluid-handling questions and needs every day.

Gary leads our Custom Fabrication Technologies business. In that role, he seeks to convert every customer problem, large or small, into an opportunity to deliver a reliable, repeatable, premium-quality solution – sometimes, if the customer visits our Pittsburgh headquarters, right on the spot. More often, though, Gary works hand-in-hand with our respective local Swagelok Account Manager and, then, key customer maintenance, safety, and operations personnel to ensure that we first fully understand the project or site application dilemma/objective. From that point, Gary will likely go on location to confirm and verify all application intel he’s gathered via phone calls and emails.

In fact, Gary relishes these site visits.

“I love the chance to work directly with our customers. When I help them over the phone or via email, that’s one thing…but it’s hard for me to effectively gauge their level of satisfaction. However, when I get out into the field and am part of the fabrication project start to finish, I can more accurately evaluate just how big a difference we’re making to a customer’s bottom line,” begins Gary. “Plus, when I visit a customer facility or jobsite to discuss a panel redo or system rebuild, I have the chance to take pictures, gather key measurements, and, best of all, learn more by directly interviewing the contact.”

Gary Osman (right) provides the design support for all Swagelok Pittsburgh | Tri-State Area Custom Fabrication projects. He’s pictured here with Mike Koster, our Fabrication Shop Manager, who builds our instrumentation panels and simple assemblies.

Next, and most critically, Gary will interact with Mike Koster, our Fabrication Manager. In short, Gary designs (using CAD software) and quotes our productivity-boosting solution. Once the project is formally approved and Gary has completed the production/delivery schedule, Mike, at times supported by Mike Gagel, our Technical Trainer, then builds it – simple assemblies to large, complex instrumentation panels – to exact specifications. Of note: All of our fabrication work is 100%-warrantied by Swagelok Company. Gary, Mike, and Mike have gone through extensive certification training and testing to perform their respective fabrication duties.

“Having the ability to oversee a fabrication job through every point in the process – that’s what makes my role so special,” states Gary.

Once in a while, though, customers simply drop by our warehouse seeking an instant and customized Swagelok answer to a perplexing system problem. These interactions with Gary have led to, literally, fabrication on the spot…especially when the visitor is under extreme time constraints.

In addition, Gary is the main Swagelok Pittsburgh | Tri-State Area go-to for incoming customer technical calls. In this daily “Technical Services” role, he informs callers, after listening at-length to their system goals and/or issues, which Swagelok components (fittings, valves, gauges, hoses, tubing…) ideally match the discussed fluid-handling applications.

“One thing I’ve learned in my six years at Swagelok Pittsburgh | Tri-State Area is to always ask a caller or visitor very specific questions around his/her intended end usage of the Swagelok products being purchased or the fabrication being discussed. That way, I can better help ensure not only the effectiveness of the Swagelok solution, but the safety of the workers and the workplace, too,” claims Gary.

Gary formerly held a Project Management position in the highway and heavy construction industry, making for a fairly seamless transition to his current job. He’s a Civil Engineering graduate of Penn State University.

“But you can’t declare a specialized engineering discipline at Penn State until you complete a variety of wide-ranging, relevant courses. My exposure to mechanical engineering aspects during my schooling truly helped prepare me for what I encounter day-to-day – and how I can continue to grow my role – at our distributorship,” says Gary.

Growing up, Gary’s Mom provided a little nudge. And the rest, as they say, is history.

“She would always insinuate that I was going to go into Engineering,” he says with a laugh. “So, from a very early age, I pretty much had my career path set: Get my Engineering degree, then go straight into the Engineering field. Mom’s advice has worked out rather well.”

A native of the Pittsburgh area, Gary now lives in the South Hills with his wife, Ashley, daughter, Stella, and a second baby on the way. Bindi, Gary’s beloved boxer, rounds out the family. In his spare time, Gary enjoys jogging and keeping physically fit. He’s also a huge fan of the Nittany Lions and the Pittsburgh area’s sports teams.

Coming soon: Engineered Excellence Blog, Part 2: Bob Sarber.