Swagelok Knows Regulators

Swagelok Knows Regulators

Swagelok industrial Regulators and supplemental support services deliver unparalleled safe, reliable, lasting, and cost-effective pressure control, especially in the most challenging fluid-system applications and operating environments.

Swagelok Pressure Regulators reliably maintain pressure levels in your industrial fluid systems – ensuring that media is contained and transferred under optimal pressures to protect you, your processes, equipment, and end products.

Here's How We Can Help Solve 5 Common Regulator-Related Challenges:

1: Choosing the "Right" Regulator

|

First, know which type you need: pressure-reducing or back-pressure? Also, does your choice have the proper inlet/outlet pressure ratings, temperature rating, flow capacity, venting, and end connections for your specific application? Our self-service assets, including sizing tools, flow curve generator, and a Jules Thompson Effect calculator, and system experts will gladly advise you on regulator selection, while also assessing your current systems. These Swagelok professionals can even design and build gas distribution subsystems for you. |

|

2: Maintaining Chemical Compatibility

|

Even if you’ve chosen the properly sized and rated component for your work, other factors could jeopardize your regulator functionality, resulting in unplanned downtime and unexpected replacement costs. Swagelok regulators are made of corrosion-resistant alloys and built to withstand the harshest environment and most daunting types of fluids, helping you minimize any potential for degradation. We also offer Materials Selection training to give you the know-how to avoid compatibility issues involving your components and system fluids. |

|

3: Combatting Contamination

|

Are particles trapped between a poppet and seat? Has fine debris accumulated over time, causing leakage and imprecise pressure control? Swagelok regulators thoroughly mitigate contamination and, if it does occur, make repairs fast and easy. Our specially designed inlet filters trap debris before it can enter the regulator. Swagelok Spare Parts Kits are available so you can make quick/simple fixes versus a complete unit replacement. |

|

4: Minimizing Pressure Creep

|

Prevent seat leakage from leading to system shutdown due to upstream pressure leaking to the downstream side of the regulator, causing overpressurization. That means your techs must then spend considerable time troubleshooting your issue to find and fix the seat damage. Workers could be put at risk if creep leads to pressure ratings exceeding maximum levels for your components. Our Swagelok Field Engineer can visit your facilities for a first-hand diagnosis of your system issues. He might suggest safety valves for your downstream operations or, perhaps, shutoff valves at the inlet of a regulator. Let us help totally minimize your safety and/or labor concerns! |

|

5: Accounting for Supply Pressure Effect

|

Don’t let SPE potentially harm your workers or profitability. In some cases, SPE could jeopardize test results when precise pressure control is absolutely required. In extreme circumstances, it could pose a risk to your laboratory staff. But, in most instances, it leads to wasted troubleshooting efforts because your gauges are showing unexpected pressure changes due to the balancing of forces and fluid dynamics during a regulator’s operation. Our Swagelok Field Engineer can educate your techs about this phenomena, while also assisting them in choosing a regulator design that will negate SPE in applications where pinpoint pressure control cannot be compromised. |

|

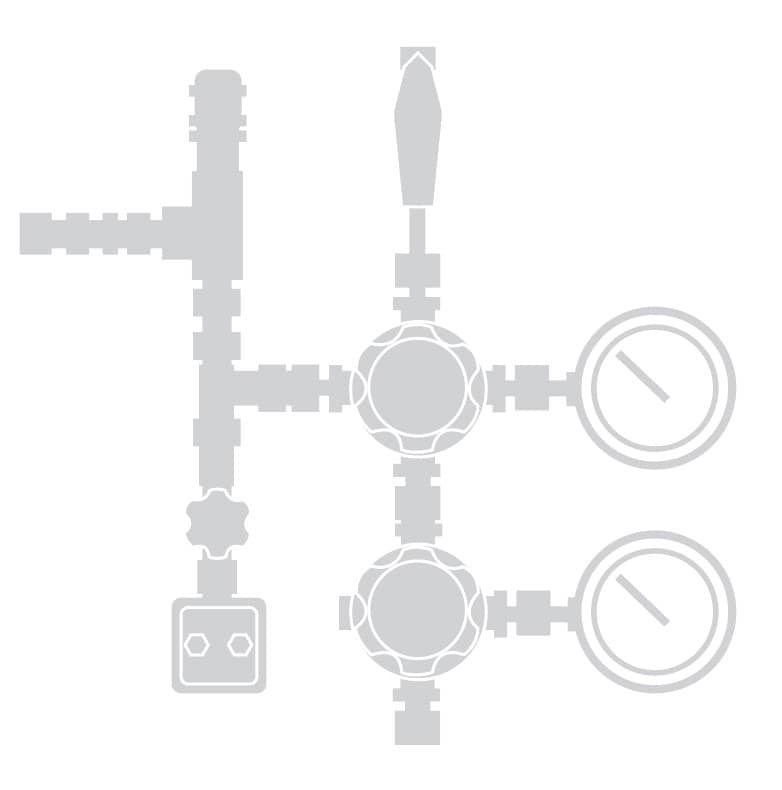

Swagelok Regulator Types:

Significantly reduce maintenance, repair, and replacement labor and costs – and stay online – by choosing from our vast array of styles that will maintain pressure, while minimizing the damaging effects of droop or creep, no matter what your flow rate.

Analytical and Instrumentation

|

K Series Regulators

|

Process

|

RHPS Regulators

|

High-Purity/High-Flow

|

HF Regulators

|

Vaporizing

|

KEV and KSV Regulators

|

Gas Cylinder Changeover

|

KCM Series Regulators

|

Tank Blanketing

|

TBRS and TBVS Regulators

|

Gas Distribution Systems

|

Get gases from a high-pressure source to where they need to go at your application’s specified flow and pressure rate. Ask about our four panel types: Swagelok Source Inlet, Swagelok Gas, Swagelok Changeover, and Swagelok Point-of-Use. |

|

For additional technical information, email Zack Barefoot, Manager – Business Development: zach.barefoot@swagelok.com.