Swagelok Knows Hose

Swagelok Knows Hose

For more than 75 years, Swagelok leak-tight componentry has helped the global Oil & Gas, Chemical, Refining, Power, Steel, Research, and other major markets employing fluid systems to stay safe, productive, efficient, and profitable. Our tube fittings, with their grip-type mechanism that creates a unique hinging-and-colleting action, deliver unsurpassed performance in even the most challenging applications – as do our valves, manifolds, gauges, tubing, and regulators

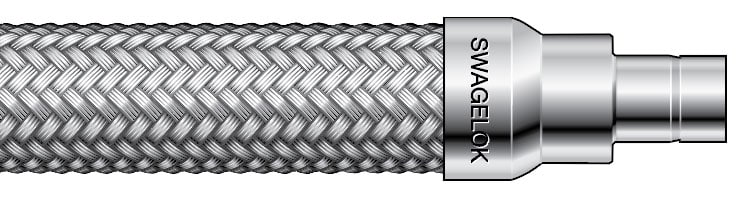

Our Industrial Hoses, though, continue to set new standards for reliable, repeatable results when you need a flexible connection between stationary and moving equipment, when a connection is temporary or disconnects are frequent, or when you must isolate from high-vibration machinery. In all these operational scenarios, hose use means far fewer connections – and, thus, substantially less potential for dangerous and costly leakage. Some basics:

RULE #1: Know that your hoses are STAMPED. In other words, apply our methodology to ensure that you’re choosing the ideal hose for the job at hand:

| SIZE | What’s the necessary OD, ID, and length for your work? |

| TEMPERATURE | of the material to be conveyed and your environment. |

| APPLICATION | What are your conditions of use? |

| MATERIAL | being conveyed. What’s its type and concentration? |

| PRESSURE | to which the assembly will be exposed. |

| ENDS | The style, type, orientation, attachment methods… |

| DELIVERY | What testing, quality checks, packaging, and other requirements are involved? |

RULE #2: Know the four primary hose core types and 11 end connections available to you:

|

|

All-Metal For High-Temperature, Medium-Pressure, Vacuum, Corrosive, or General-Purpose applications |

|

|

Fluoropolymer For Inert and Flexible applications |

|

|

Thermoplastic For High-Pressure, Low-Temperature applications |

|

|

Rubber For Flexible applications |

| 11 End Connections | Tube Stub, Tube Fittings, VCR/VCO, Tube Butt Weld, Kwik Clamps, Cam and Groove, ISO/BSP, KF, Lap Joint Flange, SAE 37 JICo (Male and Female), NPT (Male and Female) |

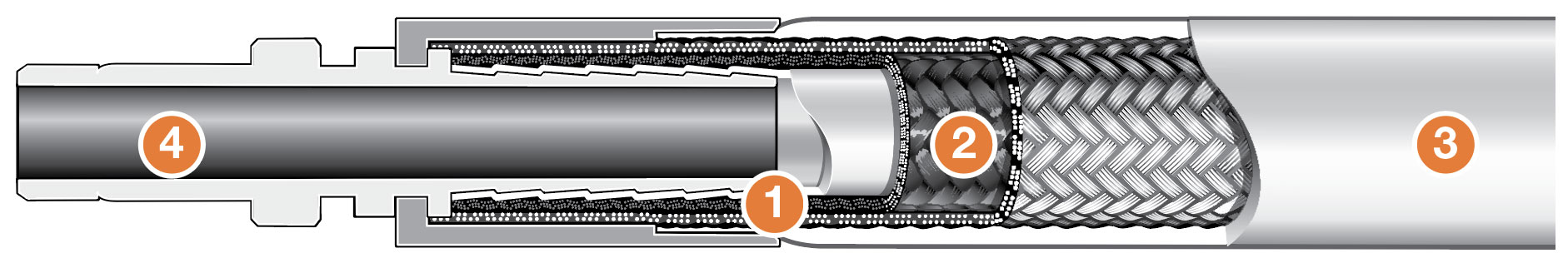

RULE #3: Know the importance of a reinforcement layer:

|

Such built-in backup strengthens the core tube axially and longitudinally to ensure that your hose can withstand increased pressures. |

|

|---|---|

|

|

|

In addition, such reinforcement delivers kink and crush resistance, electrical continuity, hoop and torsion strength, volumetric expansion control, flexibility, and force to bend. However, like hoses in general, not all hose reinforcements are of the same quality and composition. Swagelok offers and recommends braided reinforcement styles that employ wires or fibers in a strong, resilient configuration that will not untwist when your hose is pressurized, resulting in far superior longevity versus coiled models. |

|

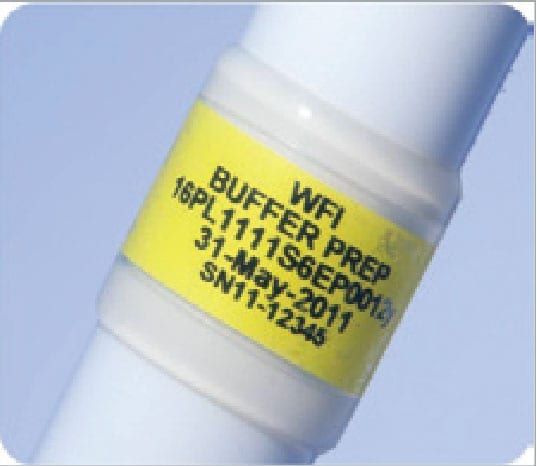

RULE #4: Know your enhancement options:

|

Choose from our six covers and/or four tags to dramatically improve service life:

|

|

|

Choose from 4 tagging options: |

|||

|---|---|---|---|

|

Lanyard - Attaches with a stainless steel lanyard and aluminum clamp. |

Clamp - Attaches with two metal bands. |

Mat - Attaches via an adhesive. |

Perma - Attaches via an adhesive. |

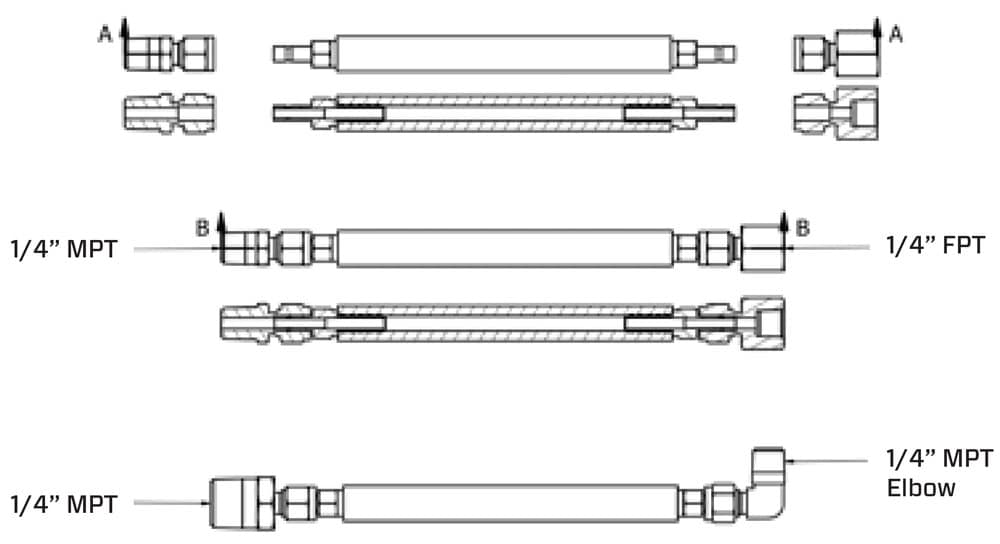

One Hose. Multiple End Connections. Numerous Applications!Bonus Hose Efficiency Tip: By stocking a few Swagelok Tube Stub Adapters and some union tees and elbows, you can easily switch out end connections to adapt the same hose for multiple applications. Our adapters eliminate difficult alignment problems, too! |

|

RULE #5: Know the unquestioned value of a comprehensive maintenance plan:

| Establish a routine to get timely and pertinent information on each hose employed within your plant or facility: service life, when installed, when last inspected, inspection frequency, location/inventory of replacement hoses, operating pressures… Developing a meaningful monitoring schedule may not be easy and will take time, but will provide measurable, cost-saving benefits, essentially ensuring that you don’t wait too long to replace a hose and run the risk of system failure, or changeout too early and lose precious uptime. |

RULE #6: Know that your nearby Swagelok distributor is always ready and able to help:

Our certified Swagelok Hose Advisor can conduct an onsite survey to look for, evaluate, and report:

Or, our Swagelok-trained fabrication master technicians can build your hose to exact specifications the first time – and every time – with all work fully warrantied by Swagelok Company. Plus, we offer renowned Swagelok Hose Safety Essentials training where you’ll learn:

|

Mike Gagel, |

Delivering Difference-Making Solutions:

Mike will walk the floor with you to thoroughly analyze your current hose applications, including critical cleaning and storage activities. They’ll then issue you a Swagelok Hose Management & Efficiency Report loaded with our expert recommendations on how you can rapidly improve and sustain your overall hose safety and health. Our Advisor will also help you set up a routine hose-maintenance schedule – enabling you to avoid lengthy downtime, excess waste, and high repair/replace costs.

For additional technical information, email Mike Gagel, Swagelok Field Engineer: michael.gagel@swagelok.com.