Safety

Your Safety Comes First –

In All We Supply and Do

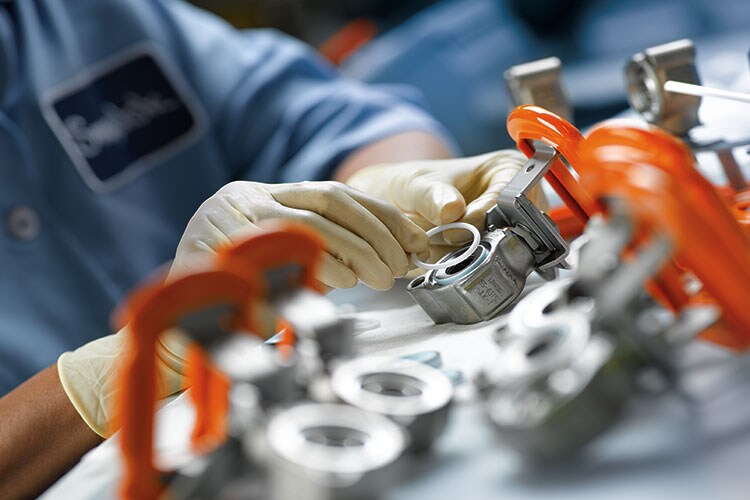

Safety: Always our first company and brand priority. We design, develop, make, and distribute the highest-quality, leak-tight products that will keep your workers, facilities, and valuable assets safe, no matter what your industry or severity/complexity of application.

Our factory personnel, our raw materials, our manufacturing/quality-control processes, our supply network... we leave nothing to chance as we secure your safety in any/every association or interaction with us.

|

From our manufacturing, inspection, and quality control procedures employed to make our componentry – to the strategic support services that we offer to complement those always leak-tight tube fittings, valves, gauges, hoses, tubing, panels, sub-assemblies, and related accessories, our first thought is always on keeping you safe, productive, efficient, and profitable. |

|

We use only premium, special-recipe “Swagelok” 316 stainless steel that exceeds ASTM minimum nickel and chromium requirements to deliver optimum ductility and corrosion-resistant results, even in your most challenging fluid-system applications and operating conditions. |

|

In addition, we own our entire manufacturing process, including all forging, machining, electro-polishing, welding, and testing activities – with everything done by our certified associates in only our facilities. We can even track what lot of materials make up a part and what components are within an assembly. |

As a global leader in providing unparalleled technical expertise to save you time, money, risk, and worry, Swagelok strongly advises:

-

Never mix tube fittings from different manufacturers

Not all products are made to the same exacting tolerances, so interchanging or intermixing brands can likely result in uneven performance, harmful emissions, costly leaks, increased maintenance labor, and even dangerous blowouts. - Minimize opportunities for mistakes

Consider mounting detailed tags on your valuable equipment and hoses to inform workers what takes place within your system so that, when necessary, they can make safe adjustments. Also try color-coding handles, tubes, and pipes throughout your facility so your maintenance personnel know precisely which fluids and gases are involved and where. To prevent accidental actuation, add a lockout on your critical process valves. - Choose the best components to match the job

Make certain you have a thorough understanding of your process conditions throughout your facility. That way, you can most confidently select those product brands that will deliver not only superior performance for your applications – but maximum worker safety, too. We also highly suggest that you buy your parts from trusted partners via authorized channels. - Remove complexity wherever Possible

One extremely effective way to dramatically improve maintenance efficiencies is to switch from threaded and/or welded piping runs to bendable tubing, greatly reducing potential leak points throughout your fluid system. Also count on suppliers who can consistently design and build instrumentation panels and enclosures, as well as simple assemblies – with all such fabrication work fully warrantied. - Carefully follow the manufacturer’s installation instructions

For example, if tube fittings are under-tightened, leakage and blowouts are likely to occur; if overtightened, the number of possible re-assemblies sharply decreases. Always make sure that your tubing rests firmly on the shoulder of the fitting before tightening. And always check for tubing ovality, defects and scratches, as well as wall thickness extremes. - Factor for machine vibration and motion in your System design

Otherwise, you risk major damage to tubing and/or cause fittings to loosen and, thus, leak. Tube supports are an excellent guard against such a possibility during high-pressure applications. Hoses are your first choice when a flexible connection is required between moving and stationary equipment, a temporary connection or frequent disconnects involved, or when complete isolation is necessary from high-vibration machinery. - Account for tubing hardness and material compatibility

Always ensure that the metal tubing used is softer than the employed fittings. Pairing brass fittings with stainless steel tubing would yield a devastating result: The fittings would simply be too soft to effectively grip the tube, leading to major leakage and safety concerns.

Swagelok Safety and Performance Support Services

|

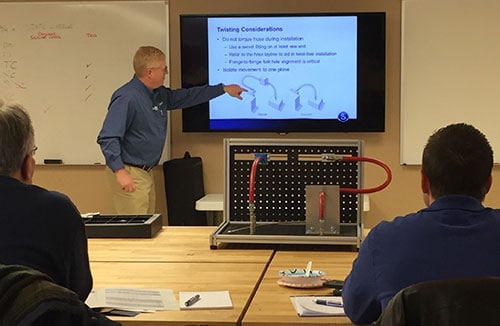

Swagelok Tube Fitting Installation & Tube Bending Safety Essentials Our all-day, highly interactive course ensures that all participants graduate fully knowing how to properly and safely assemble a fitting and bend tubing of various materials. This is not a sit-and-listen class; students are tested on their ability to immediately apply what they’ve learned. We’ll also bring our instruction to your facility or worksite. To schedule your mobile training session, simply email rudy.frank@swagelok.com. And, remember, all of our Technical Training offerings are eligible for state reimbursement and count toward Continuing Education credits! You will not make a better investment in the safety and productivity of your maintenance technicians – you have our money-back guarantee on that. |

|

Swagelok Energy-Loss Evaluations Let us help you identify and repair costly air or gas leakage within your fluid system. Such inefficiency leads to lost media, lost production, equipment damage, off-spec final product, an unsafe work environment, major cleanup, and, sometimes, even non-compliance fines – and that means dramatically and negatively impacted facility and/or project profitability. Our energy audits are free and yield a comprehensive report that not only cites your problem areas – but also gives our expert recommendations to boost system performance. To schedule your on-site survey, email rudy.frank@swagelok.com. |

|

Swagelok Hose Advisories Let us map your current industrial hose applications and storage practices. Such an audit will ensure that you’re no longer just replacing the same damaged or worn hoses – but actually moving toward an optimized overall fluid system. Our certified Hose Advisors will visit your site to conduct a complimentary, thorough analysis of your existing hose usage. We’ll then provide you a highly detailed report filled with proven advice on how to rapidly improve your hose safety and health. Plus, we’ll even help you set up a routine hose-maintenance schedule – to enable you to avoid ongoing expensive repair and replacement costs. To reserve your hose advisory, email rudy.frank@swagelok.com. |

To drastically reduce your costly and dangerous fluid-system leakage, thus optimizing worker safety, efficiency, and performance, contact:

rudy.frank@swagelok.com | 412.439.1706