Swagelok’s Small-Bore Piping System Delivers a Lower Total Installed Cost. Period.

Versus typical welded and threaded piping systems, the Swagelok Small-Bore solution is inherently safer – and simpler and faster to install and maintain. For projects involving threaded pipe, pipe stands, dies, cutting oils, sealants, and tapes are necessary. Also to be considered: assembly, testing, disassembly, rework, and reassembly. When welded pipe is employed, a qualified welder, welding equipment, consumables, weld permits, air tests, fireboxes, tacking, weld quenching, finish welding, purging, passivation, and inspections are all part of the extensive and expensive process.

Just imagine the difficulty, when either of these systems is in play, staying on-time, on-plan, and within budget.

However, Swagelok's Small-Bore piping system – basically, our unparalleled tube fittings and premium-quality tubing – means far fewer connections, and, thus, far fewer leak points.

Breaking down the specific Swagelok advantages:

Ease of Installation

Only a few simple tools are needed to install our tube fittings; no threading, flaring, soldering, or welding needed.

Lower Pressure Drop

Use of our tubing means gradual bends and smooth internal diameters.

Fewer Connections

Use of our tubing means drastically reduced chance of leakage; plus, tubing can be bent around most obstructions.

Better Strength to Weight Ratio

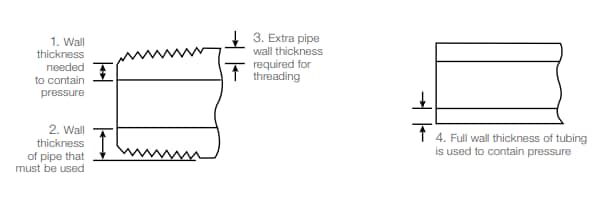

The full wall thickness of tubing contains system pressure. Pipe threads reduce effective wall thickness. Not to mention, tubing is considerably lighter – resulting in reduced transportation costs, easier assembly, less support requirements, and less space occupied.

Leakage

At high pressures, pipe connections often leak. Swagelok tube fittings, however, are leak-tight…without the use of sealing compounds. That means drastically lower operating costs, no matter how challenging the application or what the media: compressed air, steam, gas, or hydraulic fluid.

Easy Maintenance

A Swagelok tube fitting also acts as a union. So, when disassembly is required, there’s no need to disconnect a series of pipe lengths and fittings to remove any particular component from the fluid system.

Assistance from Swagelok Pittsburgh | Tri-State Area

Swagelok Pittsburgh | Tri-State Area can help you:

➢ Learn best practices for tube fitting installation and tube bending: Technical Training

➢ Never run out of critical Swagelok componentry: Industrial Vending or Vendor-Managed Inventory

➢ Identify and repair dangerous/costly leakage in your facility or worksite: Energy Evaluations

➢ Save on capital expenses: Equipment Rentals

➢ Install and maintain a higher-performing, cost-effective fluid system: Genuine Swagelok Componentry

For the complete Swagelok Small-Bore story, and for more details around all of our value-added Services and premier Products, contact us today.