Shell Makes History in Monaca

Source: Pittsburgh Post-Gazette

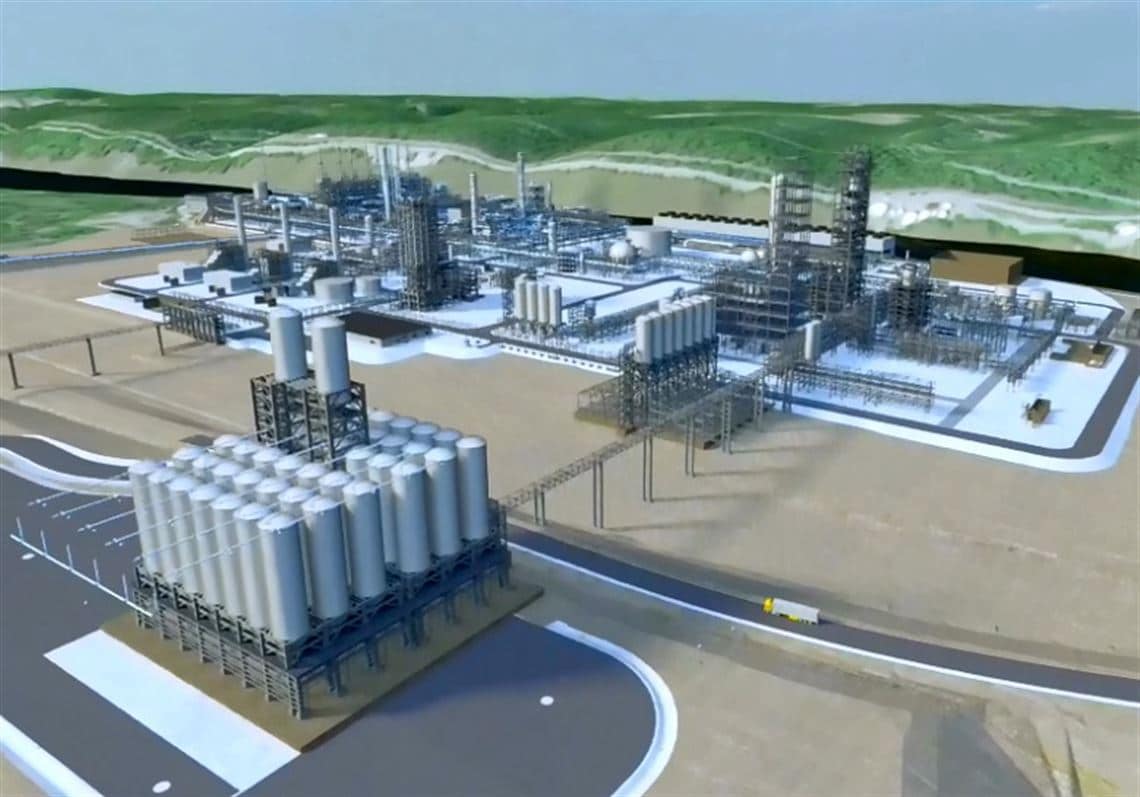

At Swagelok Pittsburgh | Tri-State Area, we're closely tracking key developments concerning the in-process Shell cracker plant in Monaca. Even now, during its construction, the site is positively impacting the local economic landscape as it further helps establish our region as a premier, national Petrochemical hub.

Some background and a few of the project's more noteworthy milestones to date:

Location: Monaca in Potter Township, Beaver County, PA (about 25 miles northwest of Pittsburgh)

Cost: $6 billion

Area: 340 acres

Start Date: November 8, 2017

Completion Date: Construction is expected to end in the early 2020s.

Purpose: To process ethane into ethylene, an important building block for plastics and other products.

Award-Winning Engineering

Named Project of the Year by the Engineers Society of Western Pennsylvania in February 2018. Here's why – after just a few months of work:

-

Crews moved 7 million cubic yards of dirt.

-

Crews built 2 bridges to support the plant.

-

Crews installed more than 48,000 feet (more than 9 miles) of underground piping.

-

Crews constructed 4 large retaining walls.

Prime Location

Shell reports that 70% of North America's polyethylene business is housed/conducted within a 700-mile radius of Pittsburgh, thus placing the plant in an ideal location to service these customers.

Job Creator

Approximately 6,000 workers will be needed to finish the construction. Six hundred more full-time employees will be needed once the plant is operational.

Tall Order

In September 2018, two of the world's tallest cranes were brought on-site. One is nearly 675 feet tall and can lift 3,500 tons. Thirty-five shipping containers, filled with sand, act as the crane's counterweight.

On October 7, 2018, another massive crane was required to move the heaviest piece of the cracker plant—a 300-foot-tall, 2,000-ton quench tower. "The quench tower will use circulating water streams to cool the cracked gas, condense hydrocarbons, and remove impurities released from the gas during the high-heat cracking process," The Times reports.

Raising the Roof

In November 2018, engineers placed a 580,000-pound roof on top of an 80-foot-tall, 8-million-gallon ethylene tank using nothing more three fans and air pressure.

About Swagelok Pittsburgh | Tri-State Area

As Southwestern and Western Pennsylvania's exclusive distributor of the world's premier brand of fluid-system componentry and value-added, truly differentiated strategic services, we're your local go-to resource for significantly improved Oil and Gas and Petrochemical safety, productivity, efficiency, and profitability. Contact us today!