Fabrication Technology 101

(left: Mike Koster, Fabrication Center Manager, and Gary Osman, Applications Engineer, discuss in-process Swagelok Pittsburgh | Tri-State Area fabrication work.)

PITTSBURGH, Pennsylvania (January 26, 2017) - Since its inception more than 50 years ago, Swagelok Pittsburgh | Tri-State Area has been your local reliable supplier of genuine Swagelok componentry for ultimate fluid-system performance, efficiency, and productivity.

But we can also provide expert and warrantied custom fabrication that can enable you to dedicate your skilled workers to more critical tasks, especially when your production schedule is tight or overloaded. From simple assemblies to large, complex panels, our three-person Fabrication Technologies team delivers exceptional design assistance and premium swaging, tube bending, orbital welding, coiling, and/or kitting support – at our state-of-the-art Fabrication Center in Pittsburgh or at your facility or project site.

The Design

Most Fabrication projects are contracted to Swagelok Pittsburgh | Tri-State Area via one of two scenarios: 1. The account’s local Swagelok Sales Associates identifies a need at the customer site, either during a routine visit or while we’re conducting a free, value-added Energy Loss or Hose Advisory audit; or 2. our customer reaches out directly to that same associate to request a quote for an internally generated ideal. In the former instance, Gary Osman, Swagelok Pittsburgh’s Applications Engineer, will work with the customer to help design a customized solution to reduce excessive labor, scrap, and rework time and costs. If the customer supplies or suggests a design, Osman immediately schedules a site visit, with our Sales Associate for the account, to ensure that we have all critical application and secondary project details prior to performing the work at our Fabrication Center in Pittsburgh.

“I always strive to get a first-hand, complete, and accurate understanding of the customer’s working pressure, temperature, flow rate, and media – the absolute essentials we need to deliver quality fabrication, whether a simple assembly or complex panel or cabinet, that will optimize the requestor’s fluid-system application,” says Osman. “I also need to ensure that whatever we add ideally complements the customer’s current system.”

In addition, Osman provides multiple options for the customer to consider that could better enable us to provide a premium-performance solution:

“For example, would meter valves work better than isolation valves? What are the environmental conditions surrounding the requested assembly’s operation? How will it be installed? These and plenty of other questions need to be asked so that what we deliver meets or, hopefully, exceeds customer expectations,” states Osman.

(Koster at work at Swagelok Pittsburgh | Tri-State Area’s 49 Meade Avenue, Bellevue, state-of-the-art Fabrication Center.)

The Build

Once the design is finalized and approved by our customer, the building process, of either the full project or, if necessary, a prototype begins. Enter Mike Koster, Fabrication Shop Manager at Swagelok Pittsburgh | Tri-State Area. On an average day, Koster works on two to three different fabrication projects, often completing more than 30 unique such jobs each month.

“My daily works varies from basic to extremely complex. Everything from simple fabrication tasks to building a regulator or hose assembly. One of my most challenging jobs was an eight-foot-long by 10-foot-high oven control panel that required an incredible amount of tube bends and thousands of orbital welds,” claims Koster.

Of course, Koster is fully certified by Swagelok Company to perform his duties – and all work is thus warrantied by the world’s premier maker of fittings, valves, gauges, and related fluid-system componentry. We specialize in delivering work that you can seamlessly and confidently plug and play within your existing system.

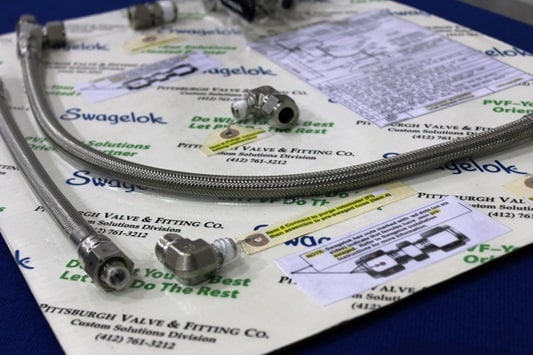

(A kitted Swagelok custom fabrication solution ready for immediate delivery.)

When Koster needs additional qualified labor support, Mike Gagel, our dedicated Technical Trainer, assists, especially when we’re asked to provide our expert fabrication skills at a customer location or at a gas-processing site in the field. Gagel is also a 20-year Swagelok Factory veteran, bringing a highly potent combination of Swagelok product, application, and technical knowledge to all of our fabrication perspectives and projects.

Our custom fabrication technologies are proven to:

- …reduce your Engineering Costs

- …reduce your Scrap/Rework Costs

- …reduce your Receiving and Inspection Costs

- …reduce your Inventory-Handling and Tracking Costs

- …reduce your Ordering Administration and Costs

- …enabling you to realize optimum labor efficiency and effectiveness!

For further fabrication capability details, please contact us:

Learn more about Fabrication Technologies

412.463.1757

412.761.3212; ext 124