The Swagelok Tube Fitting Advantage, Part II

Swagelok Tube Fitting Advantage - Part Two: Our Material Difference

In part one of our Swagelok Tube Fitting Advantage series, we detailed why our proprietary design – which yields exceptional tube contact, grip support, and an ultra-strong gas seal – makes us your superior choice for optimum fluid-system safety, performance, efficiency, and profitability, particularly in the most challenging Oil and Gas, Power, Steel, Chemical/Refining, OEM, Semiconductor, and Applied Research applications.

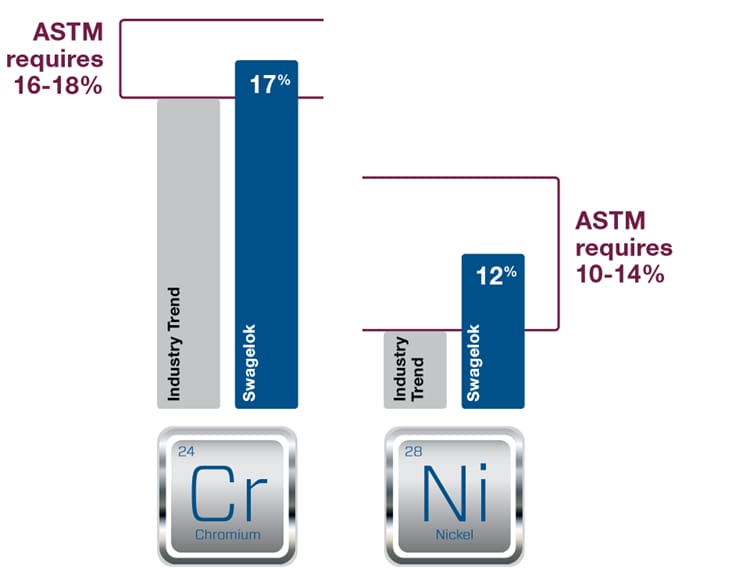

But our MATERIAL DIFFERENCE plays an equally vital role within each Swagelok tube fitting produced as well. Let’s start with the melt. We tightly control the chemistry used to make our unique, special-recipe stainless steel. No other fitting manufacturer matches our combination of 17% MINIMUM chromium and 12% MINIMUM nickel to resist corrosion, while maintaining ductility. Bottom line: We significantly exceed ASTM specifications.

In addition, we place rigid measures on all vendors who supply the 316 stainless steel bar stock used in the manufacture of our tube fittings. All raw materials are subject to extreme testing, including 100% ultrasound analysis – to identify abnormalities – and eddy current checks to detect cracks.

We’ve also performed extensive Chloride Stress Corrosion Cracking testing on the stainless steel nuts equipped on our fittings. After 700+ hours in a test environment, 72 Swagelok nuts had zero cracking or leakage; of the 110 competitive nuts checked, 43 showed cracking – and three leaked.

Swagelok tube fittings are also available (beyond Stainless Steel 316) in a wide range of alloys for those extra-demanding applications: 6 Moly, Alloy 20, Alloy 400, Alloy 600, Alloy 625, Alloy 825, Alloy C-276, Alloy 2507, and Grade 4 Titanium. All stocked standard.

Lastly, because of the elevated chromium/nickel content that’s inherent in each Swagelok tube fitting, we can offer engineered combinations that are less costly and deliver equal or better corrosion resistance versus full exotic alloy solutions for certain applications, including installation exposed to seawater.

Count on premium-quality Swagelok tube fittings to always perform under pressure – no matter how hostile the environment. Browse our complete line of styles and sizes: https://pittsburgh.swagelok.com/en. Or contact us at 412.761.3212 or info@pittsburgh.swagelok.com.

COMING SOON: The Swagelok Tube Fitting Advantage, Part 3: Excellence in Manufacturing.