Understanding Pressure-Reducing and Back-Pressure Regulators

This article and accompanying video are an excerpt from the Swagelok® Regulator Selection & Optimization Webinar presented by Swagelok Field Engineer Supervisor Jon Kestner.

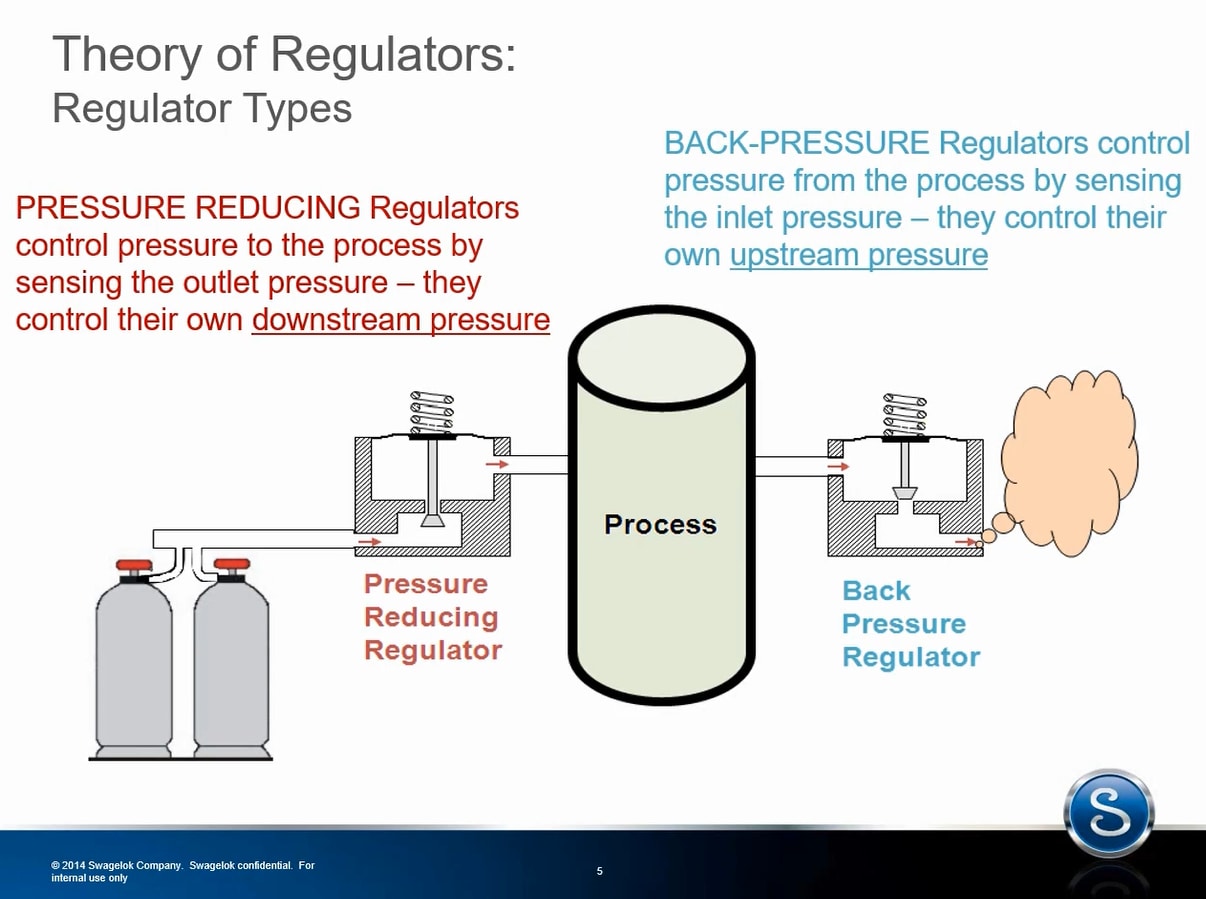

There are two main types of regulators. One is the pressure-reducing regulator and the other is the back-pressure regulator.

Understanding Pressure-Reducing Regulators

Pressure-reducing regulators do just what their name implies. They take a high-pressure source, whether it's a gas or liquid, and they reduce that pressure down to something that's usable for a process. That process can be a whole host of things. It could be a lab test bench, it could be a continuous chemical process, it could be tank filling—it could be anything.

Understanding Back-Pressure Regulators

You also have back-pressure regulators. Where pressure-reducing regulators drop pressure where you want more control over the outlet or what’s downstream of the regulator, back-pressure regulators look behind them, as the name implies. Back-pressure regulators control the upstream pressure and keep the pressure within a specified limit. You could think of back-pressure regulators as a highly-sensitive relief valve designed to relieve excess pressure. Although they don't slam open and dump a bunch of pressure, they operate in a similar way.

The Most Common Regulators in the Field

Most regulators used in industry are the pressure-reducing type. We see about 75% pressure-reducing regulators to 25% back-pressure regulators. In our Swagelok® Regulator Selection & Optimization Webinar, we spend the majority of our discussion focused on pressure-reducing regulators because that is what you’ll most commonly see while working in the field.

To learn more about regulators, watch the Swagelok® Regulator Selection & Optimization Webinar, visit our Swagelok regulators product page, or contact us at 412.761.3212.