The Swagelok Tube Fitting Advantage - Part One

Swagelok Tube Fitting Advantage - Part One: Better by Design

In 1947, Swagelok Company developed the original two-ferrule tube fitting. Since then, we’ve continued to update and improve our proprietary design for use in thousands of diverse and challenging applications in the worldwide Oil-and-Gas/Energy, Chemical/Petrochemical, Power, Steel, Semiconductor, OEM, Applied Research, and other fluid-related markets.

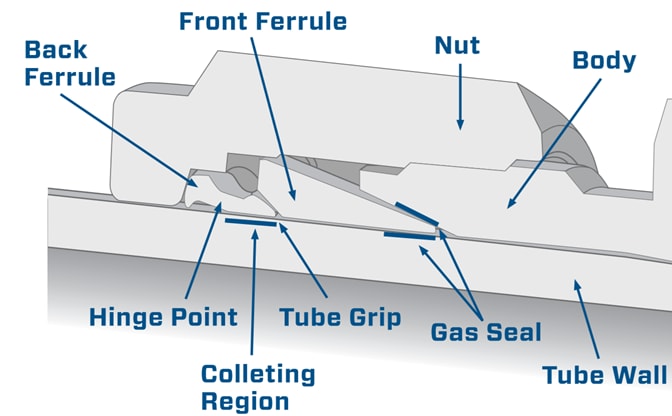

Many critical factors go into the design of a Swagelok tube fitting to ensure plant/technician safety, absolute minimal leakage, and greatly reduced overall site operating costs. First, there’s our unique hinging-and-colleting action that delivers exceptional tube contact and grip support. Competitive products employ a bite-type mechanism that can leave a sharp indent, causing damage or fracturing of the tube’s surface.

Secondly, the burnishing/polishing action of our front ferrule creates concentrated contact zones on the tube and body bevel. Result: An ultra-strong gas seal that keeps your fluid system leak-tight, preventing the release of harmful emissions.

Next, our fitting’s colleting region ideally isolates stress risers at the tube grip. That means exceptional resistance against bending, deflection, and, especially, vibration. Connections are always solid, even in applications requiring major movement and/or vibration.

In addition, our patented, award-winning SAT12® low-temperature carburization process hardens and strengthens our ferrules – without affecting their ability to fight corrosion and maintain ductility. In fact, this unique Swagelok technology, that enriches steel surfaces by diffusing carbon atoms between metal atoms without forming carbides, has been hailed as “one of the most significant material science breakthroughs in decades.”

Plus, we continually and rigorously evaluate the performance of our fittings by routinely testing (extreme burn, rotary flex, impulse, and shock impact) thousands of samples as they come off our production line. Just another step in our ongoing effort to achieve zero customer disappointments – in our products, processes, and people.

Count on premium-quality Swagelok tube fittings to always perform under pressure. Browse our full line of styles and sizes: https://pittsburgh.swagelok.com/en. Or contact us at 412.761.3212 or info@pittsburgh.swagelok.com.

COMING SOON: The Swagelok Tube Fitting Advantage, Part 2: Our Material Difference.